Drop-In Anchor AN ES

Drop-In Anchor AN ES

Group:

1401

Application

Drop-In Anchor for single fixing in non-cracked concrete and multiple fixing in cracked concrete. Suitable for fixing pipelines, channels, etc. meeting the respective approval requirements. The anchor must only be used for dry interiors. For damp locations and outdoor constructions the stainless steel version is required.

- No special drill required

- Setting tool for distance-controlled forced expansion

- Suitable for push-through mounting

Installation

As expansion tool use the respective Setting Tool for Drop-In Anchor or the Plug-on Setting Tool ASW. The “intelligent” expansion cone facilitates the mounting with bore dia. tolerances or varying concrete quality. By the controlled deformation of the cone during installation, the needed edge and centre distances are decreasing considerably.

Technical Data

Single fixing:

Extract from application conditions of ETA-10/0257

Admissible loads not affected by centre and edge distances.

Total safety factor respected according ETAG 001 ( YM YF ).

| Anchor size | M8x30* | M8x40 | M10x30 | M10x40 | M12x50 | M16 |

|---|---|---|---|---|---|---|

| Nominal diameter of drill d0 = [mm] | 10 | 10 | 12 | 12 | 15 | 20 |

| Depth of bore hole h0 = [mm] | 30 | 40 | 30 | 40 | 50 | 65 |

| Installation torque Tinst = [Nm] | 8 | 8 | 15 | 15 | 35 | 60 |

| Diameter of clearance hole in the connecting element df ≤ [mm] | 9 | 9 | 12 | 12 | 14 | 18 |

| Thread length Lth [mm] | 13 | 20 | 12 | 15 | 18 | 23 |

| Min. screwing depth Lsdmin [mm] | 9 | 9 | 10 | 11 | 13 | 18 |

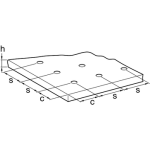

| Min. thickness of concrete slab hmin [mm] | 100 | 100 | 120 | 120 | 130 | 160 |

| Min. centre distance smin [mm] | 60 | 80 | 100 | 100 | 120 | 150 |

| Min. edge distance cmin [mm] | 95 | 95 | 115 | 135 | 165 | 200 |

| Perm. tensile load in non-cracked concrete (Screw 5.6 up to 8.8) | ||||||

| C20/25 [kN] | 3.3 | 3.6 | 3.3 | 5.1 | 7.1 | 10.5 |

| C25/30 [kN] | 3.6 | 3.8 | 3.6 | 5.6 | 7.8 | 11.5 |

| C30/37 [kN] | 4 | 4 | 4 | 6.2 | 8.6 | 12.8 |

| C40/50 [kN] | 4.7 | 4.4 | 4.7 | 7.2 | 10 | 14.9 |

| C50/60 [kN] | 5.1 | 4.6 | 5.1 | 7.9 | 11 | 16.3 |

| Lateral load (Screw 5.6) ≥ C20/25 zul. V [kN] | 3.9 | 3.9 | 4 | 4.1 | 9 | 16.8 |

| Lateral load (Screw 5.8) ≥ C20/25 zul. V [kN] | 3.9 | 3.9 | 4 | 4.1 | 11.1 | 18 |

| Lateral load (Screw 8.8) ≥ C20/25 zul. V [kN] | 3.9 | 3.9 | 4 | 4.1 | 11.1 | 18 |

| Perm. bending moment (Screw 5.6) Mzul [Nm] | 8.1 | 8.1 | 15.8 | 15.8 | 27.8 | 71 |

| Perm. bending moment (Screw 5.8) Mzul [Nm] | 10.9 | 10.9 | 21.1 | 21.1 | 37.1 | 94.9 |

| Perm. bending moment (Screw 8.8) Mzul [Nm] | 17.1 | 17.1 | 33.7 | 34.3 | 60 | 152 |

| Charact. centre distance scr [mm] | 90 | 120 | 90 | 120 | 150 | 195 |

| Charact. edge distance ccr [mm] | 45 | 60 | 45 | 60 | 75 | 97,5 |

| Loads under fire exposure steel ≥ 5.6 | ||||||

| Perm. load R30 perm. F [kN] | 0.9 | 1.8 | 0.9 | 1.8 | 3.2 | 4.7 |

| Perm. load R60 perm. F [kN] | 0.9 | 1.3 | 0.9 | 1.8 | 3.1 | 4.7 |

| Perm. load R90 perm. F [kN] | 0.8 | 0.8 | 0.9 | 1.2 | 1.8 | 3.3 |

| Perm. load R120 perm. F [kN] | 0.5 | 0.5 | 0.7 | 0.8 | 1.2 | 2.2 |

* Application for indeterminated static systems

Multiple fixing:

Extract from application conditions of ETA-10/0258

For multiple mounting solutions of non-load-bearing systems acc. ETAG 001, part 6.

Safety factor acc. ETAG 001 is included ( YM YF ).

The perm. loads per fixing point for the respective countries are regulated in ETAG 001, part 6.

| Anchor size | M8x25 | M8x30 | M8x40 |

|---|---|---|---|

| Nominal diameter of drill d0 = [mm] | 10 | 10 | 10 |

| Depth of bore hole h0 = [mm] | 25 | 30 | 40 |

| Installation torque Tinst = [Nm] | 8 | 8 | 8 |

| Diameter of clearance hole in the connecting element df ≤ [mm] | 9 | 9 | 9 |

| Thread length Lth [mm] | 12 | 13 | 20 |

| Min. screw depth Lsdmin [mm] | 8 | 9 | 9 |

| Standard/Min. thickness of component hmin1 / hmin2 [mm] | 100/80 | 100 | 100 |

| Min. centre distance smin [mm] | 50 | 60 | 80 |

| Min. edge distance cmin [mm] | 100 | 95 | 95 |

| Perm. tensile load cracked/non-cracked concrete | |||

| C12/15 and C16/20 [kN] | 1.2 | – | – |

| C20/25 to C50/60 [kN] | 1.9 | 1.7 | 2 |

| Perm. bending moment (Steel 4.6) Mzul [Nm] | 6.4 | 6.4 | 6.4 |

| Perm. bending moment (Steel 5.6) Mzul [Nm] | 8.1 | 8.1 | 8.1 |

| Perm. bending moment (Steel 5.8) Mzul [Nm] | 10.9 | 10.9 | 10.9 |

| Perm. bending moment (Steel 8.8) Mzul [Nm] | 17.1 | 17.1 | 17.1 |

| Charact. centre distance scr [mm] | 75 | 180 | 210 |

| Charact. edge distance ccr [mm] | 38 | 90 | 105 |

| Loads under fire exposure screw ≥ 4.8 | |||

| Perm. load R30 perm.. F [kN] | 0.6 | 0.9 | 1.1 |

| Perm. load R60 perm. F [kN] | 0.6 | 0.9 | 0.9 |

| Perm. load R90 perm. F [kN] | 0.6 | 0.6 | 0.6 |

| Perm. load R120 perm. F [kN] | 0.5 | 0.5 | 0.5 |

| Loads under fire exposure screw ≥ 5.6 | |||

| Perm. load R30 perm. F [kN] | 0.6 | 0.9 | 1.5 |

| Perm. load R60 perm. F [kN] | 0.6 | 0.9 | 1.5 |

| Perm. load R90 perm. F [kN] | 0.6 | 0.9 | 0.9 |

| Perm. load R120 perm. F [kN] | 0.5 | 0.5 | 0.5 |

| Charact. centre distance scr,fi [mm] | 100 | 180 | 210 |

| Charact. edge distance ccr, fi [mm] | 50 | 90 | 105 |

| Anchor size | M10x25 | M10x30 | M10x40 | M12x25 | M12x50 | M16 |

|---|---|---|---|---|---|---|

| Nominal diameter of drill d0 = [mm] | 12 | 12 | 12 | 15 | 15 | 20 |

| Depth of bore hole h0 = [mm] | 25 | 30 | 40 | 25 | 50 | 65 |

| Installation torque Tinst = [Nm] | 15 | 15 | 15 | 35 | 35 | 60 |

| Diameter of clearance hole in the connecting element df ≤ [mm] | 12 | 12 | 12 | 14 | 14 | 18 |

| Thread length Lth [mm] | 12 | 12 | 15 | 12 | 18 | 23 |

| Min. screw depth Lsdmin [mm] | 10 | 10 | 11 | 12 | 13 | 18 |

| Standard/Min. thickness of component hmin1 / hmin2 [mm] | 100/80 | 120 | 120 | 100/80 | 130 | 160 |

| Min. centre distance smin [mm] | 60 | 100 | 100 | 100 | 120 | 150 |

| Min. edge distance cmin [mm] | 100 | 115 | 135 | 110 | 165 | 200 |

| Perm. tensile load cracked/non-cracked concrete | ||||||

| C12/15 and C16/20 [kN] | 1.7 | – | – | 1.7 | – | – |

| C20/25 to C50/60 [kN] | 2.1 | 2 | 2 | 2.1 | 2.4 | 6.3 |

| perm. bending moment (Steel 4.6) Mzul [Nm] | 12.8 | 12.8 | 12.8 | 22.2 | 22.2 | 56.9 |

| perm. bending moment (Steel 5.6) Mzul [Nm] | 15.8 | 15.8 | 15.8 | 27.8 | 27.8 | 71 |

| perm. bending moment (Steel 5.8) Mzul [Nm] | 21.1 | 21.1 | 21.1 | 37.1 | 37.1 | 94.9 |

| perm. bending moment (Steel 8.8) Mzul [Nm] | 34.3 | 33.7 | 34.3 | 60 | 60 | 152 |

| Charact. centre distance scr [mm] | 75 | 230 | 170 | 75 | 170 | 400 |

| Charact. edge distance ccr [mm] | 38 | 115 | 85 | 38 | 85 | 200 |

| Loads under fire exposure ≥ 4.8 | ||||||

| Perm. load R30 perm. F [kN] | 0.6 | 0.9 | 1.5 | 0.6 | 1.5 | 4 |

| Perm. load R60 perm. F [kN] | 0.6 | 0.9 | 1.5 | 0.6 | 1.5 | 4 |

| Perm. load R90 perm. F [kN] | 0.6 | 0.9 | 1.1 | 0.6 | 1.5 | 3 |

| Perm. load R120 perm. F [kN] | 0.5 | 0.7 | 0.9 | 0.5 | 1.2 | 2.4 |

| Loads under fire exposure screw ≥ 5.6 | ||||||

| Perm. load R30 perm. F [kN] | 0.6 | 0.9 | 1.5 | 0.6 | 1.5 | 4 |

| Perm. load R60 perm. F [kN] | 0.6 | 0.9 | 1.5 | 0.6 | 1.5 | 4 |

| Perm. load R90 perm. F [kN] | 0.6 | 0.9 | 1.5 | 0.6 | 1.5 | 3.7 |

| Perm. load R120 perm. F [kN] | 0.5 | 0.7 | 1.0 | 0.5 | 1.2 | 2.4 |

| Charact. centre distance scr,fi [mm] | 100 | 170 | 170 | 100 | 200 | 400 |

| Charact. edge distance ccr, fi [mm] | 50 | 85 | 85 | 50 | 100 | 200 |

Valid are the values of the mentioned approval which can be seen on our website www.sikla.com/downloads.

| Material: | Steel, galvanised |

Approvals / Conformity

For the multiple use for non-structural applicatons Sikla approval ETA-10/0258 (M8 – M12), for installation in non-cracked concrete Sikla approval ETA-10/0257, fire protection testing, VdS-conform, FM-Approval ≥ M10

Drop-In Anchor AN / AN ES – ETA 10/0257PDF | 2.4 MB

Drop-In Anchor AN/AN ES ETA 10/0258PDF | 3.9 MB

FM – Sikla Anchors ANPDF | 187.3 KB

1) Delivery date on request – goods are procured order-related.